Industrial Boiler Engineering

Since its establishment, Selnikel has been providing high-quality and highly efficient solutions for industrial heating systems for the needs of its customers. With our industrial boiler and burner know-how, we provide bespoke design, engineering and documentation, manufacturing, project management, and installation services for all kinds of industrial applications

Contact Us

Our Industrial Boiler Systems

Selnikel combines tailor-made industrial engineering services

with reliable, long-lasting, and efficiency-oriented

steam and heating systems.

Explore Our Container Type Boiler Room Solutions

We are proud to be a global supplier to the world's largest power plants. We manufacture boiler room solutions in water tube and fire-tube types. We provide

bespoke boiler room production for all kinds of special needs and according to different capacities.

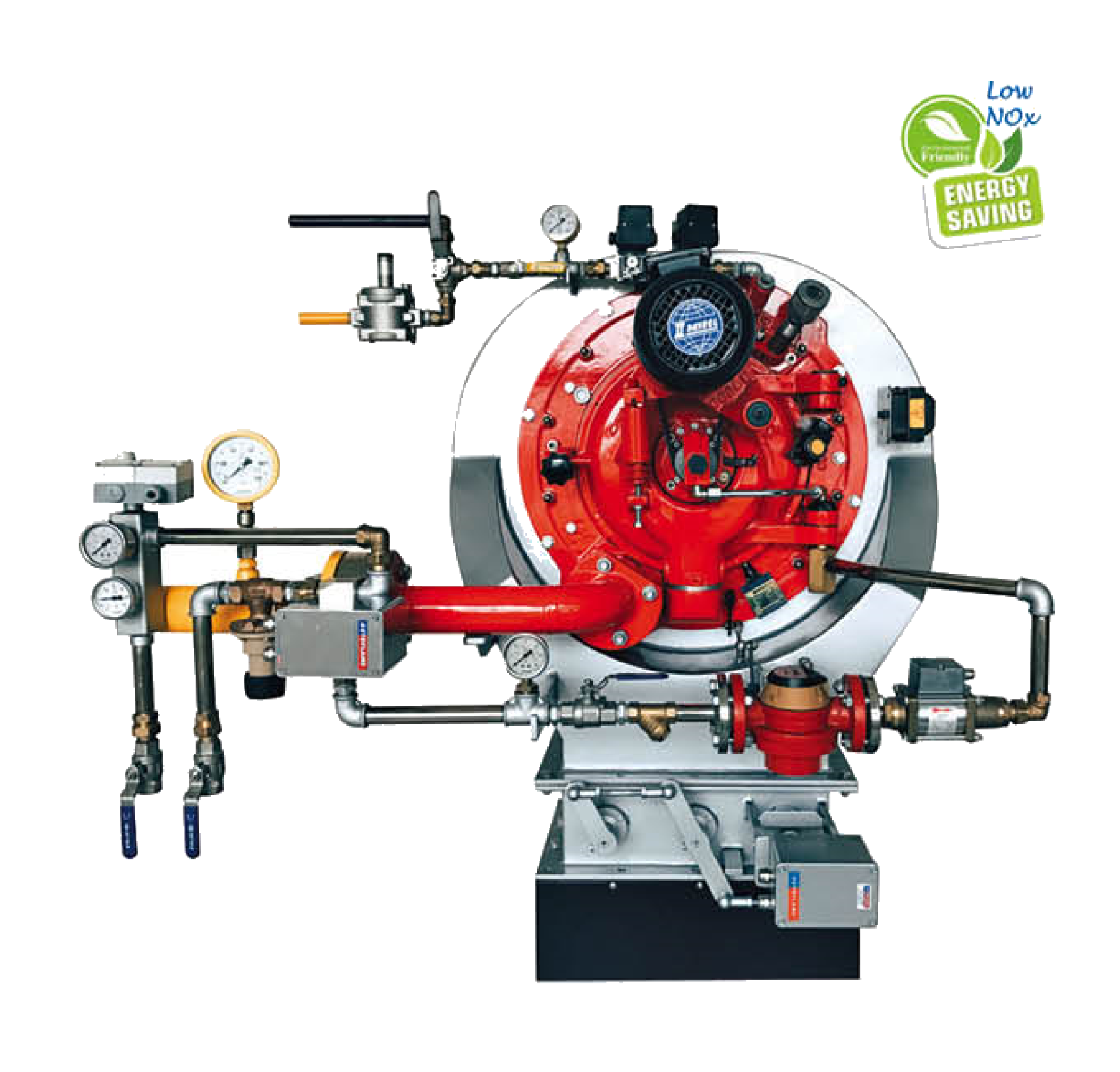

Industrial Burners

Features

- Raysel industrial burners have being manufactured since 1986 in Selnikel premises under the license of German "Ray Öl-und Gasbrenner GmbH" company.

- Selnikel also provides professional solutions to its customers in burner service and maintenance.

Burner Types

- Gas Burners

- Oil Burners

- Biogas Burners

- Gas / Oil Burners

Contact Us

Frequently Asked Questions

1What are the Advantages of Using Steam ?

Steam carries a high amount of heat energy, provides constant temperature heat transfer, provides homogeneous temperature distribution on the materials and surfaces to be heated.

It does not need energy to transport the steam, does not contain foreign matter and is hygienic. Compared to hot water and superheated water installations, it requires smaller serpentine surfaces in the steam installation.

It does not need energy to transport the steam, does not contain foreign matter and is hygienic. Compared to hot water and superheated water installations, it requires smaller serpentine surfaces in the steam installation.

2What is Flre Tube Type Boiler ?

Fire tube type boilers are high efficiency, large water volume, full cylindrical steam and superheated water boilers.

It is manufactured in accordance with TS 377- EN 12953 standards with a flat cylindrical combustion chamber, a single or double furnace, three-pass, liquid and gas fueled from corrugated sheet metal. It is the most common type of boiler used in industrial facilities.

3What are the Advantages of Water Tube Boilers ?

Water Tube Boilers are highly efficient. They can reach 95% efficiency when properly designed. The boiler water volume consists of pipe and drum. Since the system does not contain large water volumes, the risk of explosion is low and can operate at high pressures comfortably.

Water Tube Boilers can produce steam quickly due to their lower water volumes. In this way, they can meet the need for high flow and pressure values without difficulty. Their economic life is very high when water with appropriate operation and required properties is used.

Water Tube Boilers can produce steam quickly due to their lower water volumes. In this way, they can meet the need for high flow and pressure values without difficulty. Their economic life is very high when water with appropriate operation and required properties is used.

4What is the Use of Water Tube Type Boilers ?

Water Tube Steam Boilers are used in industrial facilities where high capacity and pressure are needed. Water tube boilers consist of membrane walls arranged vertically between one or two drums and sealed between them by welding with a flat bar.

These membrane walls are connected to the drama by upper and lower collectors. Inside these walls, the Fire chamber consists of the evaporator and the superheater (depending on the temperature of the steam). At the gas outlet of the boiler, there is an economizer to increase the boiler efficiency.The water tube boiler is designed and produced according to the EN 12952 standard.

These membrane walls are connected to the drama by upper and lower collectors. Inside these walls, the Fire chamber consists of the evaporator and the superheater (depending on the temperature of the steam). At the gas outlet of the boiler, there is an economizer to increase the boiler efficiency.The water tube boiler is designed and produced according to the EN 12952 standard.

5What is Condensate Tank ?

The condensate tank is the tank where the condensed steam used in the system is returned. However, in cases where it is not possible to rotate all of the steam used in the system in the form of condensate, the difference is completed with the city mains water passing through water softening. The softened water is connected to a level control while the condensate tank is fed directly. System size is important in sizing the condensate tank.

The condensate tank volume is generally chosen to meet the boiler capacity of 1 hour. To avoid cavitation, the tank level should be above the pump suction.

6What is a Deaerator ?

Deaerators are used in steam plants to separate the gases dissolved in the water and to heat the water sent to the boiler (to 102°C). There are dissolved gas components such as oxygen, nitrogen and carbon dioxide in the feed water sent to the boiler. Of these gases, oxygen and carbon dioxide are corrosive. The oxygen (O2) in the water should be reduced to 0.005 mg/m3. CO2 must be completely removed.

If these gases are not separated from the water, they cause significant corrosion in the steam and water pipes. In the feed water tank, the feed water sent to the boiler is heated with steam. The steam is fed by a control valve that takes control from the water temperature. The second feed is made from the bottom of the dome to the steam volume, the pressure of this steam must be reduced by 0.2 bar to the saturation pressure corresponding to 102-103 °C with the help of a pressure reducer. Additional feed water and condensate returning from the system enters the deaerator from the upper part of the dome.

Steam with a low pressure of 0.2 bar is supplied from the lower part of the dome. While the water entering the dome is filtered in small drops from the perforated cascade plates, it moves downwards and comes into contact with the low-pressure steam advancing upwards. As the temperature of the water rises thanks to the meeting with the steam in small drops, the dissolved gases are also thrown out.

If these gases are not separated from the water, they cause significant corrosion in the steam and water pipes. In the feed water tank, the feed water sent to the boiler is heated with steam. The steam is fed by a control valve that takes control from the water temperature. The second feed is made from the bottom of the dome to the steam volume, the pressure of this steam must be reduced by 0.2 bar to the saturation pressure corresponding to 102-103 °C with the help of a pressure reducer. Additional feed water and condensate returning from the system enters the deaerator from the upper part of the dome.

Steam with a low pressure of 0.2 bar is supplied from the lower part of the dome. While the water entering the dome is filtered in small drops from the perforated cascade plates, it moves downwards and comes into contact with the low-pressure steam advancing upwards. As the temperature of the water rises thanks to the meeting with the steam in small drops, the dissolved gases are also thrown out.